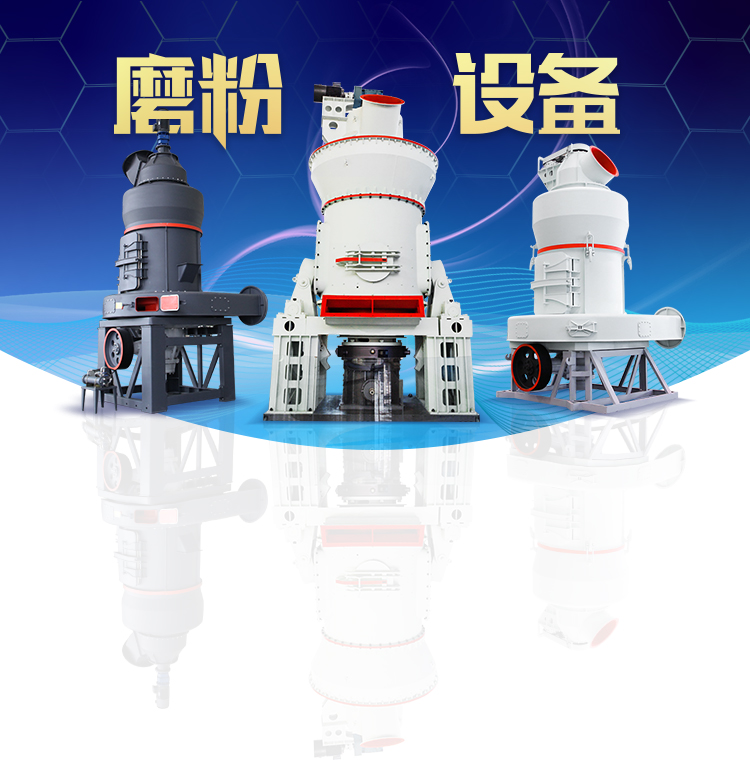

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

双面大圆机

.jpg)

大圆机 Santoni 圣东尼官网

圣东尼针织机器有限公司提供5种不同型号的单/双面的大圆机: 1ATLAS(超细针距无沉降片的单面针织圆机) 2ZENIT(单面4跑道针织圆机) 3ZENIT 24 JE(单面电子提花针织圆机) 4PULSAR(双面棉 双面多功能棉毛罗纹针织大圆机,每英寸2路/21路/25路/28路喂纱。 三角座针筒为4跑道针盘为2跑道。 圆筒机。 可用于生产罗纹、棉毛和八锁罗纹织物。 规格 评论JT系列双面罗纹针织大圆机 JingMei 精镁官网一、针织大圆机特点 1、产量高:目前大圆机的转速均可达20转/以上,34路/英寸,以34英寸筒径为例。 每可编织20402720横列,是机织的10倍以上。 2、品种多:产品适用于衣着、窗帘、床品等家纺类和工 针织大圆机基础知识上二下四跑道双面针织大圆机是一种功能全面的双面针织大圆机,可高效地编织罗纹类与双罗纹类双面织物。 在上下盘各配置了两跑道织双面布及仿复式凹凸组织用三角,在下盘三角座可装放四跑道三角。双面针织大圆机 百度百科

.jpg)

双面类针织大圆机简介纺织技术中心 纺机网

双面类针织大圆机主要有下列几种: 1、罗纹机 罗纹机是双面大圆机的一个特殊机型。 它具有1+1针道(针盘一个针道,针筒一个针道)、2+2针道、2+4针道以及4+4针道。 利用 双面剖布针织大圆机,每英寸21路喂纱。 三角座针筒为4跑道针盘为2跑道。 开幅机。 具备双面机的一切特性,又具有剖布机的卷布无折痕等特性。JT系列双面剖布大圆机 JingMei 精镁官网Leadsfon牌高产双面针织大圆机,型号DJC20/24,可编织平纹、双面布、氨纶、网眼织物,可制作运动服、泳衣等。 查看详情双面针织大圆机 Double Jersey Circular Knitting Machine高精度双面细针开幅机龙纬LONGWEI针织机械大圆机 采用高精密度心脏,双传动轴设计,加高加厚大盘,使得机器更加稳定,延长织针使用寿命,布面平白如纸。 除了具备普 高精度双面细针开幅机龙纬LONGWEI针织机械大圆机

.jpg)

CNA 一种全棉高支强捻针织双面布的制备方法

CNA CN20A CN2A CNA CN A CN A CN A CN 2 A CN2 A CN 2A CN A CN A CN A Authority CN China Prior art keywords fabric preparation yarn sided double Prior art date Legal CNB CN32A CN3A CNB CN B CN B CN B CN 3 A CN3 A CN 3A CN B CN B CN B Authority CN China Prior art keywords polylactic acid layer fabric moisture inner layer Prior art date 202111 CNB Google PatentsCNA CN32A CN3A CNA CN A CN A CN A CN 3 A CN3 A CN 3A CN A CN A CN A Authority CN China Prior art keywords polylactic acid fabric layer moisture inner layer Prior art date 202111 CNA Google PatentsUSA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine

.jpg)

USA Cloth winding device for circular knitting machine

USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine CNA CN92A CN9A CNA CN A CN A CN A CN 9 A CN9 A CN 9A CN A CN A CN A Authority CN China Prior art keywords preparation cotton knitting spinning yarn Prior art date CNA 一种针织仿毛保暖面料的制备方法 Google USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine

.jpg)

USA Cloth winding device for circular knitting machine

USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine Provided is a method for preparing a knitted woollike warm fabric, comprising the following steps: 1) raw material selecting and blending; 2) spinning process; 3 WOA1 Method for preparing knitted woollike warm USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine

.jpg)

USA Cloth winding device for circular knitting machine

USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine

CNA 一种具备自动压紧机构的布片彩绣机

CNA CN36A CN3A CNA CN A CN A CN A CN 3 A CN3 A CN 3A CN A CN A CN A Authority CN China Prior art keywords fixed piston cloth piece rotating shaft fixed box Prior art date 202306 USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine

.jpg)

USA Cloth winding device for circular knitting machine

USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a CNA CN20A CN2A CNA CN A CN A CN A CN 2 A CN2 A CN 2A CN A CN A CN A Authority CN China Prior art keywords fabric preparation yarn sided double Prior art date Legal CNA 一种全棉高支强捻针织双面布的制备方法 CNB CN32A CN3A CNB CN B CN B CN B CN 3 A CN3 A CN 3A CN B CN B CN B Authority CN China Prior art keywords polylactic acid layer fabric moisture inner layer Prior art date 202111 CNB Google PatentsCNA CN32A CN3A CNA CN A CN A CN A CN 3 A CN3 A CN 3A CN A CN A CN A Authority CN China Prior art keywords polylactic acid fabric layer moisture inner layer Prior art date 202111 CNA Google Patents

.jpg)

USA Cloth winding device for circular knitting machine

USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine CNA CN92A CN9A CNA CN A CN A CN A CN 9 A CN9 A CN 9A CN A CN A CN A Authority CN China Prior art keywords preparation cotton knitting spinning yarn Prior art date CNA 一种针织仿毛保暖面料的制备方法 Google

USA Cloth winding device for circular knitting machine

USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine USA US07/605,338 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cloth gears shaft cloth winding gear Prior art date Legal status (The legal status is an assumption and is not a USA Cloth winding device for circular knitting machine

粉磨机热机打的慢

--用花岗岩矿石制粉设备

--湖南水矿石立磨械

--气压磨粉机双气缸和单气缸哪个好

--硅矿石粉碎设备硅矿石粉碎设备硅矿石粉碎设备

--花岗石加工技术

--生产镁石灰石颗粒的设备叫什么

--矿石磨粉机利润矿石磨粉机利润矿石磨粉机利润

--矿石磨粉机2PLF7080

--水泥砼路面粗集料试验要求

--石灰石机维修

--金相研磨機上海

--如何催讨未到还款期限的合同债务

--辽宁海城东升磨粉机

--徐州奔马机械制造厂

--有没有12V电瓶带动磨煤机

--江西黑滑石磨粉机专卖

--英华矿石磨粉机

--电厂用脱硫石灰粉的包装电厂用脱硫石灰粉的包装电厂用脱硫石灰粉的包装

--生产泥炭土的设备

--玻璃矿石磨粉机5目颗粒玻璃矿石磨粉机5目颗粒玻璃矿石磨粉机5目颗粒

--重钙粉微粉磨什么厂家好

--石灰石粉立磨砂粉同出设备砂粉一体机型号大全

--新沂市踢球山矿西石英砂石灰石厂

--上海粉碎机磨辊 强力

--华新水泥立磨型号

--稀土矿的开采中的粉碎工艺

--46方解石微粉磨

--碳酸钙松散堆积密度

--矿渣粉的粉磨设备

--